Curious about the process of making a pinball machine? Look no further, Pinball Adventures is here with some information

Process of Manufacturing A Pinball Machine

Design

While a new pinball game took only 20-30 hours to manufacture, the design process was far more protracted. Designing a new game took a team of professionals from 12-18 months, and the investment cost could run up to a million dollars. Games were designed by teams, with members taking on specialized tasks. The team included a game designer, who came up with the game concept and generally organized the other members; a software developer; an artist to come up with the backglass art and playing field graphics; a mechanical engineer, responsible for the design of all the gadgets on the playing field; a sound designer to create the music and other sound effects for the game; a mechanical designer, who brought together the drawings and designs from other team members; an animator to animate images on the scoring display; an electrical engineer and a cable designer to work out the circuitry and wiring; sculptors and model-makers to build the prototype devices for the playing field, and a publications writer to write the technical documents and manuals. The team might include other people, as well, such as someone who kept track of the cost of materials, and people working in marketing, sales, and licensing.

The design work starts with a concept, which might be an original idea or might come from a licensed product, such as a movie. After the concept is agreed upon, the design team works on the layout of the playing field. Designers fiddle with placements of any special elements the game will have, and try to work out how the player will make shots leading to the element. The placement of ramps, flippers, kickers, tilt mechanisms, and such is planned out, while the mechanical engineer produces prototypes for the special elements.

After the playfield design is more or less completed, the team then produces what is called a whitewood version of the game. This is a bare plywood prototype of the

playfield. The designers use computer assisted design (CAD) software to record their plans, and this software is then used to control a computer-driven routing machine that cuts the board. The game elements for the whitewood are made by hand and glued on. Lights, ramps, and flippers are added. The whitewood may go through many revisions, as placements are changed or elements taken off or added. When the design seems satisfactory, the whitewood is wired to make it playable. Meanwhile the software developer has been creating the unique software to control the game. Williams, the last major American pinball manufacturer, had developed its own proprietary pinball operating system so that a basic framework could be used for each game, simplifying the design process. The software developer also works with the lighting and sound designers and animators to run all these effects. At the whitewood stage, the designers can actually play the game they have created, and work on developing rules.

Meanwhile the artist creates sketches for the backglass. If the game is based on a licensed theme, the artist needs to submit sketches for approval to the licensing agency. When the whitewood is near its final form, the artist makes sketches for the playfield. Pinball artists in the 1990s utilized traditional media such as pen and ink and paint, as well as computer graphics.

While the game is in development, team members keep constant track of how much the game might cost to make. If parts need to be ordered from an outside vendor, the team needs to retrieve estimates from the suppliers. The game has a total budget, and sometimes the cost of one spectacular effect means that other game elements, such as lighting, have to be redesigned to make them cheaper. The design team also creates a bill of materials, listing every part needed to make the game. Parts are ordered so that everything is in place when the game is ready to be mass produced.

After the design is finalized, workers at the plant assemble 10-20 prototypes. These are completely finished games, just like ones that will eventually be sold. The prototypes help the production plant determine that all the parts fit together, that the suppliers have sent the correct parts, and that mass production will go smoothly. Any glitches in the assembly are caught at this stage. And if any part of the manufacturing process needs to be modified, it is discovered now. The prototypes are also used for testing.

Raw Materials

The raw materials for pinball are not extraordinary. Inexpensive, sturdy plywood is used for the playfield, wiring boards, and cabinet. Metal parts, such as screws and springs, are made out of a variety of common materials, such as stainless steel and aluminum. Special elements on the playfield may be of molded plastic. Manufacturers require vendors to supply parts exactly to specifications, and to hold down production costs, which are considerable, the cheapest materials possible may be used.

Process of Manufacturing A Pinball Machine

Pressuring the playfield

- 1 Almost all the production of a pinball game is done by hand. The exception is the manufacture of the playfield. The design for the playfield is programmed into a special machine. Workers load plywood into the machine, and it squeezes each board under high pressure. The pressure incises each side of the board with marks, which show where all the assembly units go.

Screen printing

- 2 Pinball backglasses and playing field art are made by the silk-screen printing process, also called stencil printing. This is usually done by an outside vendor. From the artist’s design, the printer makes a series of patterns called stencils that break down the design into four colors. That is, all the red parts of the design are isolated on one stencil, all the blue on another, and so on. Through combinations of four colors, every possible shade can be made. The stencils are made of a sieve-like fabric. Ink will pass through the open weave of the fabric and adhere to the material being printed. The printer lays the stencil, which might be a thin, plastic laminate, down on the material. An applicator sprays the color. Then the stencil is lifted, the material briefly dried, and the next stencil laid down. After the fourth color, the design is complete. For a backglass, the whole design could be screened as one piece. For the playfield, the artwork is broken up into small sections. At the pinball factory, workers punch out the sections and adhere them to the playfield. This way, the artwork is made to fit around the holes for the targets and other mechanical parts.

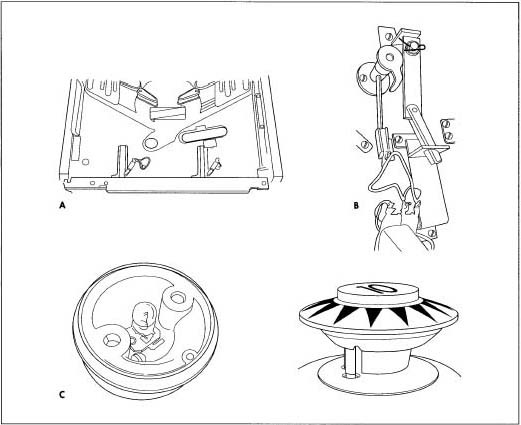

Hand assembly

- 3 Most of the remaining work is done by hand. Some of the small parts, such as spring-loaded bumper mechanisms, may have to be put together at the factory from components parts. Then these parts are assembled on the board. The wiring is very complicated. Workers painstakingly connect the wires, using screw drivers and soldering guns. The cabinets are made as rectangular hollow boxes. Workers screw rails on to hold the circuit boards and playfield. The screened art for the backglass is inserted in the backglass assembly, and that part attached to the main cabinet. Each game has close to 1,000 parts. The whole game takes from 20-30 hours to finish, and the factory itself requires about 1,000 workers.

Quality Control

Most of the quality control in pinball manufacturing is done before mass production begins. Individual parts from vendors are inspected and measured to make sure they are to specification. But the main check the manufacturer has on total product quality is in the prototypes made after the design process is complete. These 10-20 prototypes are tested in a variety of ways, including playability, general safety, and ability to withstand shipping. One is played on regularly, for field testing. One prototype is tested for sturdiness during shipping-this suffers a drop test. Another is sent to a private laboratory for a safety test, to make sure players could not be injured by the game. Other prototypes are used for publicity photographs, for the rules or manual writer, and perhaps for display at trade shows or promotions. Even after the prototypes pass inspection, the manufacturer might make a small run of some 50-100 games, just to make sure that everything is set in the production room for a bigger batch.

Thanks for reading the process of manufacturing a pinball machine!

PINBALL ADVENTURES

Pinball Adventures is a North American manufacturing company producing fresh and unique Pinball machines. Our goal is to create to the highest standards, and spark the same joy we found as gamers when we rolled our first quarter into that coin slot so many years ago. Stemming from a lifelong passion, Pinball Adventures is created by gamers, for gamers. We strive to bring high quality, innovative, and captivating experiences for all to enjoy.

Visit our website at pinballadventures.com and also check out our new Instagram page for more updates https://www.instagram.com/pinballadventures/

Pinball, Pinball Adventures, Pinball Buzz, Pinball, Pinside, History of Pinball, Pinball News, Pinball Updates, Origin of Pinball, Pinball Skill Shots, Pinball Canada, Vancouver Pinball, pinball relates to real life, collect pinball, shooter rods, Parts of a pinball machine, Move a pinball machine, most expensive pinball machine, guide to playing pinball, Largest Pinball Collection, hardest pinball game, 5 Classic Pinball Machines, Owning a pinball machine, 5 Cool Pinball Art From The 80’s , New Led Zeppelin Pinball, 3 Greatest Older Pinball Machine Process of Manufacturing A Pinball Machine